Behind the smooth working of machines, there are small components quietly doing heavy work. One such component is the v belts that transfers motion from one part to another. Many industries rely on this simple yet powerful solution every single day. Without it, production would slow down, machines would stop, and costs would rise.

What makes this even more interesting is how these belts appear in places most people never think about. From food on your plate to the ride you take, their role is bigger than it seems. Let’s explore the nine industries that depend on them for daily operations—and why they simply cannot do without them.

1. Automotive Industry

The automotive sector depends heavily on belt-driven systems. These belts help power key vehicle functions that drivers rely on without a second thought.

Why they matter

- Support engine-related systems

- Help run cooling and charging functions

- Keep vehicles operating smoothly

Even a small belt issue can lead to noise, overheating, or a complete breakdown. That’s why regular checks are critical in this industry.

Note:

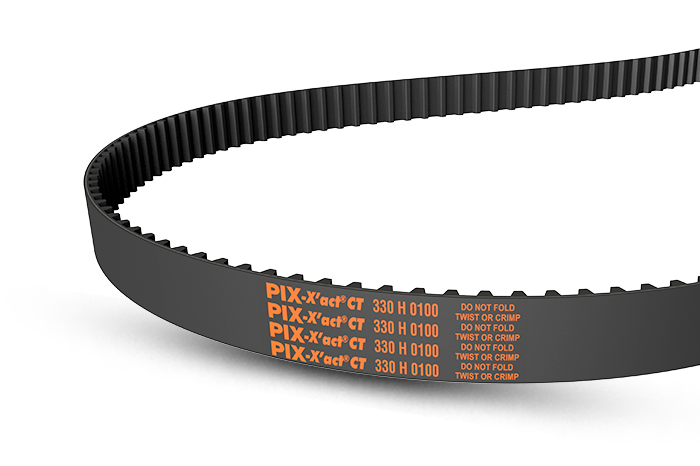

If you want to explore reliable solutions for industrial motion needs, V Belts(correas trapezoidales) play a key role across many sectors. Pix Spain supports industries with practical knowledge and dependable options. Contact them to learn more about suitable solutions for your operations.

2. Agriculture and Farming

Modern farming is powered by machines, not just manpower. Tractors, harvesters, and irrigation systems depend on belt-driven motion to work efficiently.

Daily impact

- Drives harvesting and planting equipment

- Supports grain processing machines

- Helps reduce manual labor

When these systems fail during peak seasons, farmers can lose valuable time and crops.

3. Manufacturing and Production Plants

Factories run on timing and coordination. Conveyor systems, mixers, and cutting machines all depend on belts to stay in motion.

Key benefits

- Smooth flow of materials

- Reduced machine downtime

- Reliable daily output

A single failure can stop an entire production line, which makes maintenance a top priority.

4. Food and Beverage Industry

From milling grains to bottling drinks, food processing equipment relies on steady motion to maintain hygiene and speed.

Why belts are essential

- Support mixers, grinders, and packers

- Help maintain consistent production

- Reduce handling time

Food safety and timing are everything here, and reliable motion systems play a big role.

Industry Usage Overview

| Industry | Common Machines Used | Main Purpose |

|---|---|---|

| Automotive | Engines, cooling systems | Power transfer |

| Agriculture | Tractors, harvesters | Field operations |

| Manufacturing | Conveyors, cutters | Continuous production |

| Food & Beverage | Mixers, packers | Safe processing |

5. Construction Industry

Construction sites are full of heavy machines working long hours under tough conditions. Belts help keep equipment running reliably.

Daily uses

- Power cement mixers

- Support crushers and loaders

- Assist lifting equipment

Any delay on-site can increase costs and push deadlines, making dependable systems essential.

6. Mining and Quarrying

Mining equipment operates in harsh environments with dust, heat, and constant load. Motion systems must be strong and reliable.

Why they are trusted

- Handle continuous heavy work

- Support crushers and conveyors

- Reduce manual effort

This industry relies on durable solutions that can withstand extreme conditions day after day.

7. Textile Industry

Textile mills operate at high speed. Spinning, weaving, and finishing processes need steady motion to maintain fabric quality.

Role in daily work

- Drive looms and spinners

- Maintain production speed

- Reduce fabric defects

Even a small slowdown can affect output quality and delivery timelines.

8. Power Generation

Power plants use rotating systems to generate electricity. Motion transfer plays a silent but vital role here.

Why it’s critical

- Supports generators and fans

- Helps cooling systems function

- Keeps operations stable

Any interruption can affect large areas, making reliability non-negotiable.

9. Logistics and Warehousing

Warehouses depend on conveyor systems to move goods quickly and safely.

Daily advantages

- Faster order processing

- Reduced manual handling

- Smooth material flow

As online shopping grows, this industry’s dependence continues to increase.

Where These Industries Overlap

| Industry | Risk if System Stops | Impact Level |

|---|---|---|

| Manufacturing | Production loss | High |

| Agriculture | Crop delay | High |

| Logistics | Delivery slowdown | Medium |

| Power | Service disruption | Very High |

This overlap shows how deeply connected these systems are to everyday life.

Final Thoughts

These industries may seem different, but they share one common need: reliable motion to keep things moving. The next time you switch on a machine, eat packaged food, or drive a vehicle, remember that unseen systems are working nonstop behind the scenes.

FAQs

1. Why are these belts used across so many industries?

They offer simple design, steady motion transfer, and easy maintenance, making them suitable for many machines.

2. What happens if a belt fails during operation?

It can cause machine downtime, production delays, and higher repair costs.

3. Are these systems only used in heavy industries?

No, they are also widely used in food processing, logistics, and textiles.

4. How often should belts be checked?

Regular checks are recommended, especially in industries with continuous operation.

5. Can proper maintenance reduce downtime?

Yes, timely inspection and replacement help avoid sudden failures.

Social Links

Facebook: https://www.facebook.com/pixgermanygmbh/

Instagram: https://www.instagram.com/pixgermanygmbh/

YouTube: https://www.youtube.com/user/pixtrans

LinkedIn: https://www.linkedin.com/company/pixgermanygmbh/

Twitter: https://x.com/pixgermanygmbh

Google Maps: https://maps.app.goo.gl/Ls83bzangT1ipdQv5

For more informatic content visit gettonews