Electrical systems often rely on small components that rarely get attention, yet they play a major role in safety and reliability. One such component is the Blade Fuse. It quietly protects circuits from overloads and short circuits that could otherwise damage equipment or create safety hazards. Found in cars, industrial equipment, and everyday electronic devices, the Blade Fuse has earned its place as a dependable solution for modern electrical protection.

Why the Blade Fuse Matters

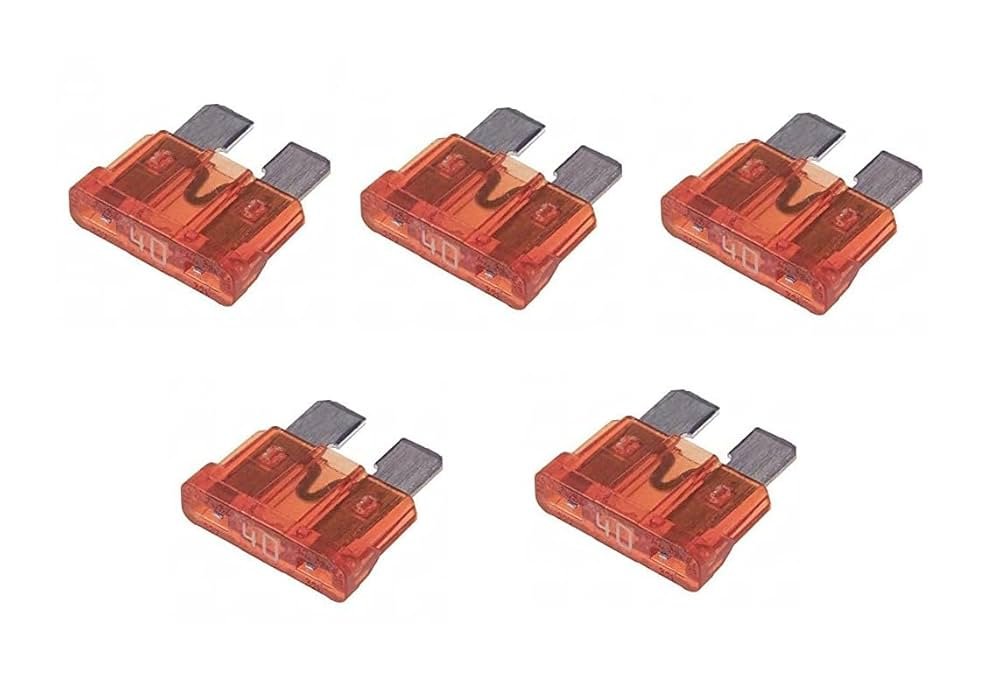

A Blade Fuse is designed for low voltage systems and is easy to recognize by its flat metal blades and compact plastic body. These blades allow it to plug securely into a socket, creating a stable electrical connection. Inside the casing, a thin metal strip is carefully designed to respond to excessive current. When current rises beyond safe limits, this strip melts and interrupts the flow of electricity.

This simple action helps prevent overheating, wiring damage, and costly equipment failure. Color coded bodies and clear markings also make it easier to identify the correct rating, even during quick maintenance or roadside repairs.

How a Blade Fuse Protects Electrical Circuits

Simple Operation with Reliable Results

During normal operation, a Blade Fuse allows electricity to flow freely. Trouble begins only when something goes wrong, such as a short circuit or unexpected overload. In such cases, heat builds up rapidly inside the fuse element. Once it reaches a critical point, the element melts and breaks the circuit. This quick response limits damage and protects the rest of the system.

The Importance of Choosing the Right Rating

Selecting the correct fuse rating is crucial. A fuse that is rated too low may blow repeatedly, even under normal conditions. On the other hand, a fuse rated too high may not react quickly enough during a fault. Blade Fuse ratings are clearly displayed, helping ensure proper selection and dependable protection.

Types of Blade Fuse Used Today

Blade fuses are available in different sizes to meet the needs of various electrical systems.

- Standard Blade Fuse

This is the most commonly used type and is widely seen in automotive fuse boxes and general electrical panels. It offers a good balance of durability, availability, and compatibility.

- Mini and Micro Blade Fuse

As vehicles and electronics have become more compact, mini and micro blade fuses have grown in popularity. These smaller versions provide the same level of protection while saving valuable space.

- High Current Blade Fuse

Some circuits handle higher electrical loads. High current blade fuses are built for these applications, offering strong protection without sacrificing ease of installation.

The Role of the Blade Fuse Holder

A Blade Fuse Holder is just as important as the fuse itself. It keeps the fuse firmly in place and ensures consistent electrical contact. A well designed Blade Fuse Holder helps prevent loose connections, reduces vibration related issues, and supports stable performance over time.

Available in inline, panel mount, and circuit board mount designs, these holders make installation flexible and maintenance straightforward. Using the right Blade Fuse Holder improves overall system safety and reliability.

Where Blade Fuse Is Commonly Used

The Blade Fuse is trusted across many industries because it combines simplicity with effectiveness.

Automotive Systems

In vehicles, a Blade Fuse protects essential systems such as lighting, audio units, power windows, and control modules. Its fast action helps reduce the risk of damage when electrical faults occur.

Industrial and Commercial Equipment

Industrial control panels often use blade fuses to protect control circuits and auxiliary systems. Their standardized design allows quick replacement, helping minimize downtime during maintenance.

Consumer Electronics

Many electronic products rely on blade fuses to protect internal circuits, especially in low voltage applications where space and reliability are both important.

Blade Fuse and Semiconductor Fuse Differences

A Blade Fuse is ideal for general circuit and wiring protection. A Semiconductor Fuse, however, is designed to protect sensitive electronic components like power transistors and rectifiers. A Semiconductor Fuse reacts much faster and limits energy more precisely to prevent damage to delicate parts.

In advanced electrical systems, both fuse types are often used together. The Blade Fuse handles overall circuit protection, while the Semiconductor Fuse focuses on safeguarding sensitive electronics.

Benefits of Using a Blade Fuse

The continued popularity of the Blade Fuse comes from several practical advantages.

- Easy installation and replacement

- Clear visual indication when blown

- Wide range of current ratings

- Compact size for organized layouts

These benefits make the Blade Fuse a reliable and cost effective choice for everyday electrical protection.

Selecting the Right Blade Fuse

Choosing the right Blade Fuse involves understanding the circuit load, voltage level, and operating environment. Matching these factors ensures consistent protection. Using a durable and compatible Blade Fuse Holder further improves reliability, especially in systems exposed to vibration or temperature changes.

Final Thoughts The Blade Fuse remains a trusted part of modern electrical systems. Its straightforward design, quick response, and broad range of applications make it suitable for vehicles, industrial equipment, and electronic devices alike. When paired with a quality Blade Fuse Holder and supported by specialized protection such as the Semiconductor Fuse, it delivers a balanced and dependable approach to electrical safety.