Introduction

The North America Polyether Ether Ketone (PEEK) market is witnessing steady expansion as industries increasingly demand high-performance materials capable of operating under extreme conditions. PEEK is a semi-crystalline thermoplastic polymer known for its exceptional mechanical strength, chemical resistance, thermal stability, and lightweight properties. These characteristics make it a preferred alternative to metals in high-end engineering applications.

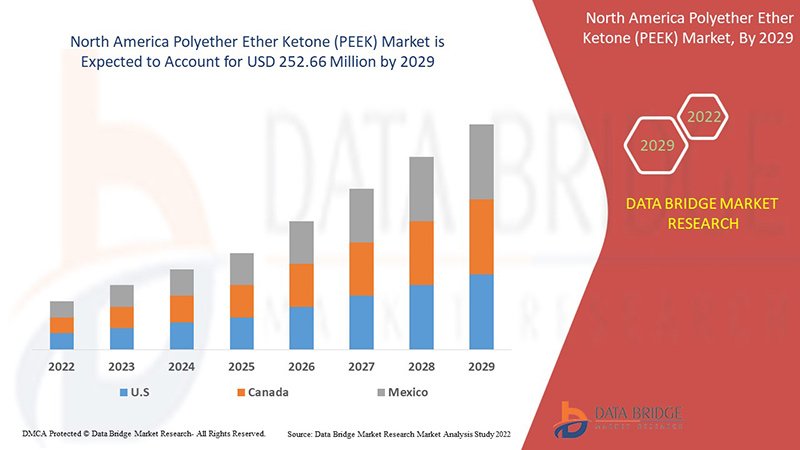

North America, led by the United States, holds a prominent share in the global PEEK market due to strong industrial infrastructure, advanced manufacturing capabilities, and heavy investments in aerospace, medical, automotive, and electronics sectors. As industries focus on efficiency, durability, and sustainability, the adoption of PEEK continues to accelerate across the region.

Market Overview

Polyether Ether Ketone belongs to the polyaryletherketone (PAEK) family and is widely used in environments where conventional plastics fail. In North America, demand is fueled by innovation-driven industries that require materials capable of withstanding high temperatures, mechanical stress, and harsh chemicals.

The market is characterized by:

- Rising use of PEEK as a metal replacement

- Strong presence of medical device manufacturers

- Continuous advancements in additive manufacturing and polymer processing

- Increasing focus on lightweight and fuel-efficient solutions

With ongoing research and development, manufacturers are expanding product portfolios to meet specialized industry requirements.

Key Growth Drivers

1. Expansion of the Aerospace Industry

The aerospace sector is one of the largest consumers of PEEK in North America. Aircraft manufacturers increasingly use PEEK components for brackets, fasteners, cable insulation, and structural parts due to their lightweight nature and resistance to high temperatures and chemicals. Replacing metal parts with PEEK helps reduce aircraft weight, improve fuel efficiency, and lower maintenance costs.

2. Rising Demand from the Medical Sector

PEEK has become a critical material in medical and healthcare applications due to its biocompatibility, radiolucency, and resistance to sterilization processes. In North America, it is widely used in:

- Spinal implants

- Orthopedic devices

- Dental implants

- Surgical instruments

The growing aging population, increasing surgical procedures, and technological advancements in medical implants are significantly boosting market growth.

3. Automotive Lightweighting Trends

Automotive manufacturers in North America are focusing on reducing vehicle weight to meet fuel efficiency and emission standards. PEEK is increasingly used in under-the-hood applications, transmission components, and electrical systems where high performance and durability are required. The rise of electric vehicles further supports demand, as PEEK offers excellent electrical insulation and thermal management properties.

4. Growth in Electronics and Electrical Applications

The electronics industry relies on PEEK for connectors, insulation components, and semiconductor manufacturing equipment. Its ability to perform reliably in high-temperature and high-voltage environments makes it ideal for advanced electronic applications, particularly in North America’s well-established electronics and semiconductor industries.

Key Applications

Aerospace

- Aircraft interiors and structural components

- Wire and cable insulation

- Engine and fuel system components

Medical

- Spinal cages and trauma implants

- Prosthetics and dental components

- Surgical tools

Automotive

- Gears, bearings, and seals

- Fuel system and transmission parts

- EV battery components

Industrial and Energy

- Oil & gas components

- Chemical processing equipment

- Seals and compressor parts

Electronics

- Semiconductor handling equipment

- Electrical connectors and insulation

Technological Advancements

Innovation plays a vital role in shaping the North America PEEK market. Manufacturers are focusing on:

- Carbon-fiber-reinforced PEEK for enhanced strength and stiffness

- 3D printing of PEEK components, enabling rapid prototyping and customized parts

- Improved processing techniques to reduce production costs

Additive manufacturing, in particular, is opening new opportunities by allowing complex geometries and faster production cycles, especially for aerospace and medical applications.

Challenges and Market Constraints

Despite its advantages, the PEEK market faces certain challenges:

- High material and processing costs compared to conventional plastics

- Limited awareness among small-scale manufacturers

- Requirement for specialized equipment and expertise

However, as production technologies advance and economies of scale improve, these challenges are expected to gradually diminish.

Regional Insights

The United States dominates the North America PEEK market due to:

- Strong aerospace and defense industries

- Advanced healthcare infrastructure

- High R&D spending

Canada and Mexico are also witnessing steady growth, supported by expanding automotive manufacturing and increasing industrial applications.

Competitive Landscape

The North America PEEK market is moderately consolidated, with key players focusing on:

- Product innovation

- Strategic collaborations

- Capacity expansions

Companies are also investing in sustainable manufacturing practices and recycling initiatives to align with environmental regulations and corporate sustainability goals.

Get More Details:

Future Outlook

The future of the North America Polyether Ether Ketone (PEEK) market looks promising. Continued growth in aerospace, medical devices, electric vehicles, and electronics will drive sustained demand. Additionally, advancements in additive manufacturing and high-performance composites are expected to unlock new application areas.

Tags: #PEEKMarket #PolyetherEtherKetone #NorthAmericaMarket #HighPerformancePolymers #EngineeringPlastics #AdvancedMaterials #AerospaceMaterials #MedicalPlastics #AutomotiveMaterials #IndustrialPolymers #LightweightMaterials #AdditiveManufacturing #3DPrinting #ElectricVehicles #SemiconductorIndustry