Polypropylene (PP) woven fabrics have been indispensably used in a number of industries because it provides the most benefit, including strength, cost effectiveness and versatility. A material composed of weaving polypropylene yarns into a durable sheet, that creates the perfect combination of strengths and also has good abrasion resistance while possessing high tensile strength., can be used repeatedly. With the increasing trend towards sustainable and high-performing materials, the role of a trusted PP fabric supplier becomes more important. India has emerged as one of the leaders worldwide in this industry, led by PP woven sacks manufacturers who are known for their innovative working style and high quality standards that cater to extensive customer needs and have made India an influential exporter.

Manufacturing Excellence and Unique Characteristics of PP Woven Fabric

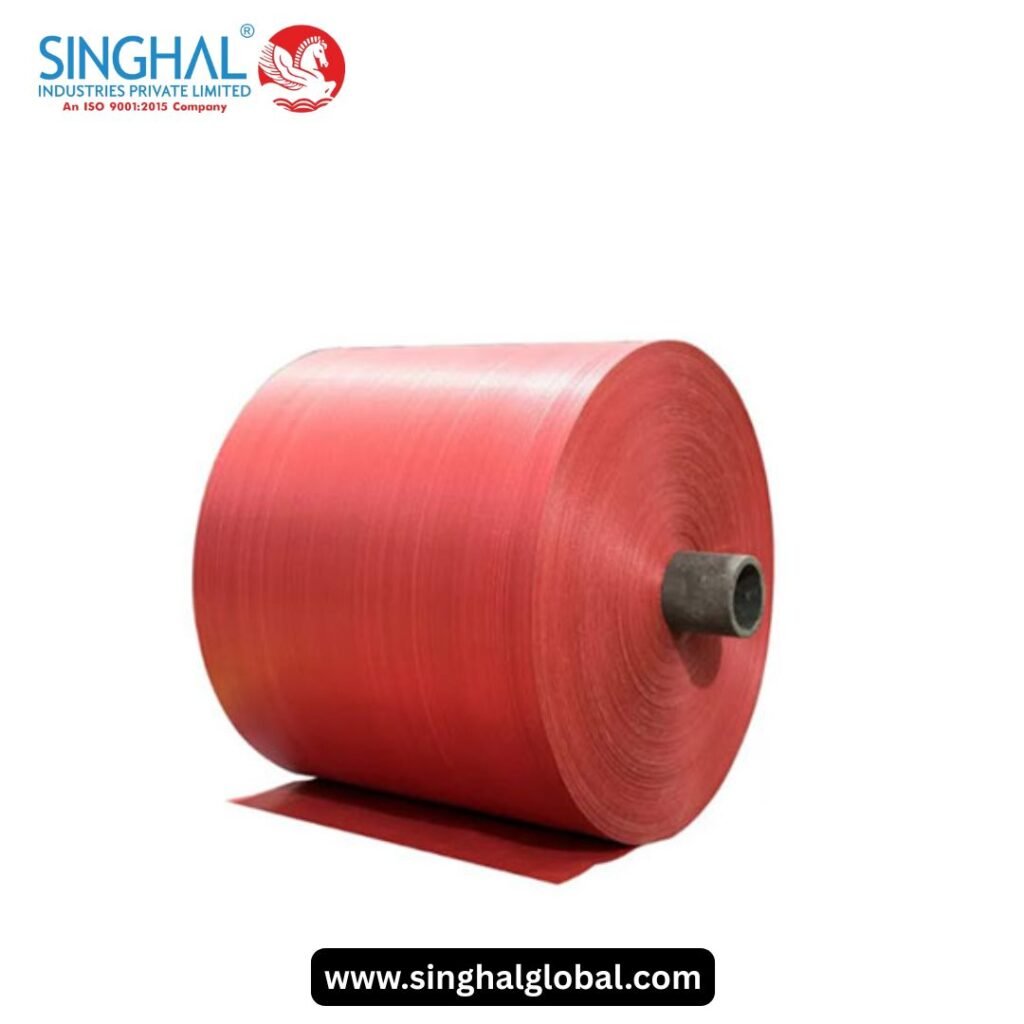

The PP fabric manufacturer is a complex process, starting from Polypropylene (PP) resins which are converted into an Agglomerate form. These fibers are weaved at high speed on looms creating a fabric with high tensile strength, tear strength and chemical stability. The PP woven fabric roll is the standard type that this material is made available in—large, easy to handle rolls of can be cut and stitched into whatever shape or size as desired. The base fabric is typically further improved by lamination, coating, or printing with added properties that include weather resistance, UV protection, or product branding. This versatility makes it an ideal packaging solution for everything from food crops and industrial products, to cement or chemicals. The particular combination of strength, flexibility and customization is why PP woven fabric continue to be the top choice for many industries.

Why PP Woven Fabric Continues to Lead in Packaging Solutions

Some aspects that make PP woven fabric irresistible in packaging space are its exceptional characteristics. Its tensile strength is up to 60 pounds, so you can pack heavy items without worry of them ripping through the clear packaging, and its moisture resistance inhibits moisture from compromising contents or causing the bag itself to deteriorate. Added to this, the breathability and water resistance of the fabric make it perfect for seed covers, crop protection or erosion control mats in agricultural contexts. Printing logos and product information directly on to the fabric is a marketing opportunity for industrial packaging and brand awareness. Indian PP woven sacks manufacturers utilize these features to manufacture tailor-made sacks in accordance with the requirement of particular clients focusing on durability, appearance and cost efficiency. The low-cost of raw material and local manufacturing proficiency add to India’s strength as a global supplier.

India’s Rise as a Global Leader in PP Woven Sacks Manufacturing

India: India’s leading producer of PP woven sacks status is attributed to technology, manpower and large domestic market. The manufacturers of PP woven sacks in India also are specialists in supplying high quality products which are based on international standards. Machine manufacturers can choose from various options including multi-color printing, water-resistant lamination and anti-static coatings for specific industry applications. Their state-of-the-art facilities also manufacture PP woven fabric rolls in multiple widths, weights and finishes (from 40″ wide to 95″ wide, from 70 G/Sq Yd. To 150 G/Sq Yd.) handling the scope of small runs to bulk quantities. Competitive rates combined with a focus to eco friendly practices and sustainable methods have made Indian products most sought after in all over the world. In addition to that trend of going green, the Indian manufacturers are shifting towards biodegradable and recyclable packaging which cater for a boost in their global packaging business.

Expanding Horizons: Applications and Sustainability of PP Woven Fabric

Although it is most commonly used in the bags, PP woven fabric roll is also widely applied to agriculture, building construction, retail industry and environmental protection due to cross-usage. The permeability and robust construction make it the perfect material for use as a crop cover, weed barrier, or in a variety of other applications. In construction, it is available for stabilization of soil and drainage systems. Printed PP woven bags are used by retail brands for both utility and brand promotion. Sustainability is another major focus for the ranking. Its recyclable and reusable nature means that PP woven is also an eco-friendly alternative to traditional single-use plastic. Biodegradable options from many of the major producers are under development which degrades faster without compromising on structural integrity, matching up with a push worldwide to cut back on plastic waste. So here is some of the new PP woven fabric products that still, throw a FAT punch… environmentally sound to boot!

Future Outlook: Innovation and Sustainability in PP Woven Fabric

The future of PP woven fabric will be extended and developed continuously. Work continues on developing bio-degradable selections that remain tough and long-lasting. Novel finishing mechanisms such as anti-microbial coatings and intelligent fabric performance attributes are being investigated in order to extend the applications of PTF. Rising preference for sustainable packaging alternatives across the globe is also driving manufacturers to innovate and improve. India’s strong manufacturing base, combined with the entrepreneurial spirit have given India a lead role in these futuristic developments. With industries focusing on sustainability, it is essential to have inclusion of recycled PPT and biodegradable material in woven. The history of PP woven fabric Today the success of pp woven fabric represents a combination of strength, durability and flexibility with its use likely to continue for many years ahead.

Conclusion

In summary, PP woven sacks manufacturers in india is an ideal blending of sustainability, strength and flexibility. From agriculture to construction and industrial packaging, retail and beyond in terms of applications show its versatility and importance. When come to company image and marketing, A reliable pp fabric manufacturer is a must. India PP woven sacks manufacturers have proved it very well by providing the products that are not only strong but also environment friendly. As sustainability becomes more important, continued advancements in biodegradable and recyclable fabrics will mean PP woven fabric continues to play a key part in global packaging options. With its adaptability and sustainability, carbon fiber is an enduring choice for the industries wanting power, value and eco-conscious bottom line solutions.

Frequently Asked Questions

- What makes PP woven fabric different from other textiles?

PP Woven Fabric has good tensile strength, is chemical resistant and can be custom printed & coated as per the customer’s requirement. - Who are the main PP fabric manufacturers?

PP woven fabric is produced by numerous manufacturers in the world and India is leading with its capacity and innovation. - What are common uses of PP woven fabric?

It is used for sack, bag, geotextiles, agriculture and industrial covering because of his strength and weather resistance. - Can PP woven fabric be eco-friendly?

Yes, especially if made with recycled or biodegradable polypropylene, which is more sustainable. - What is a PP woven fabric roll?

It’s a big continuous length of woven fabric rolled on a roll for cutting and making stuff. - Who is the largest supplier of PP Woven Fabric?

Singhal Global PVT Ltd is a supplier of PP Woven Fabric, but not necessarily and the largest in the world. The largest supplier of PP Woven Fabric varies based on region and demand on the market. - Who is the largest exporter of PP Woven Fabric?

Singhal Global PVT Ltd may be a recognized exporter of PP Woven Fabric, but it is not typically identified as the largest exporter worldwide. - Who is the largest manufacturers of PP Woven Fabric?

Singhal Global PVT Ltd is one of the manufacturers of PP Woven Fabric, but it is not generally recognized as the largest manufacturer worldwide. - How durable is PP woven fabric in harsh conditions?

It is ideal for tough environments as it resists water, chemicals, UV and tear. - What trends are shaping the future of PP woven fabric?

Biodegradable materials, smart finishing capabilities and environmental production processes are creating its future.